Revisiting Jamaica's Clarendon Rum Distillery

In November 2023, I revisited four Jamaican rum distilleries to extensively photograph their rum-making process. In this post, I’ll cover Clarendon Distillers Ltd. Despite its status as Jamaica’s second-largest distillery, it’s often overlooked by enthusiasts smitten by the rums of Hampden Estate, Worthy Park, and Appleton. Only New Yarmouth gets less attention than Clarendon. But as you’ll see from the photos below, Clarendon has much to offer Jamaican rum aficionados. Along with Long Pond, its sister distillery, Clarendon forms the backbone of National Rums of Jamaica and the Monymusk brand.

Before venturing inside Clarendon, let’s first brush up on the distillery’s background via its entry in Modern Caribbean Rum, excerpted here:

Clarendon Overview

The full history of Clarendon distillery is both complex and sparsely documented. The distillery site was once known as Monymusk Estate and consisted of both a sugar mill and a distillery, which later split into separate entities. Monymusk Estate is within the Clarendon parish, and the two names are essentially synonymous regarding sugar and rum production.

Rum distillation at Monymusk dates to at least 1794. In 1884, C.J. Ward—the same fellow who owned Appleton Estate—purchased Monymusk. The Lindo Brothers assumed ownership of both Monymusk and Appleton in 1916, and an Applemony branded rum soon followed.

United Fruit Company purchased Monymusk in 1929, then sold it to the West Indies Sugar Company (WISC) in 1937. The following year, WISC announced plans to build a central rum distillery at “Old Monymusk.” That distillery didn’t last long, as a bigger factory (“New Monymusk”) was built in 1949.

WISC operated Monymusk until 1976 when it came under Jamaican government control to prevent its closure; by 1978 the rum-making operations were renamed Clarendon Distillers Ltd. In 1980, management of the Clarendon, Long Pond, and Innswood distilleries merged to form National Rums of Jamaica.

Today, Clarendon is effectively two adjoining distilleries with shared infrastructure. The older section, believed to date to the 1949 expansion, houses the pot stills and their associated fermenters. The new portion, completed in 2009, contains a column still and modern fermentation equipment.

The 2009 addition included many additions and improvements, including:

New fermentation infrastructure and a multicolumn still

New 25,000 liter (5,500 imperial gallon) copper double-retort pot still

New boiler

New 500 kW steam turbine co-generation package

New water treatment system

New wastewater/vinasse disposal system

New cooling system including spray pond/ cooling tower basin

Clarendon’s expansion was partially funded by the EU’s Caribbean Rum Sector Program and was a showcase example of the program’s goals.

Clarendon operates between January and October each year, making approximately 15 million LAA. As such, it’s among the Caribbean’s bigger distilleries.

The Clarendon distillery supplies rum for Monymusk, NRJ’s house brand. It also sells rum in bulk to customers, including E&A Scheer, local Jamaican brands such as Port Royal and Smatt’s, and Diageo, who uses it in certain Captain Morgan blends.

Clarendon Photos (2023)

Clarendon isn’t open for public tours, so my visit was facilitated by Michael Dunkley, NRJ’s group operations manager. Because we were a very small group, there was plenty of time to peer into every corner and ask countless questions of Michael, who generously handled the onslaught.

Clarendon can be considered two distilleries from two very different eras in very close proximity. The pot still section is visually and operationally similar to Hampden and Long Pond. Just 50 meters away, the column distillation area section utilizes the latest 21st-century technology to keep light rum production running at peak efficiency and repeatability.

The annotated image above shows Clarendon’s layout. You can further explore the surrounding environs via this link to Google Maps.

As you emerge from the fields surrounding Clarendon, the distillery isn’t the first thing you’ll notice. Instead, it’s the hulking Monymusk sugar factory that has been idle since 2018. The sugar factory and distillery were once two parts of the same company until the 1980 formation of National Rums of Jamaica split them up.

Clarendon’s multicolumn still structure is the distillery’s most recognizable feature due to its height. An open-air fermentation structure adjoins and connects to it via an elevated walkway.

An elevated level within the fermentation structure enables access to the four massive, 200,000-liter fermentation tanks that feed the column still. The control room for column still operations is also located on this level.

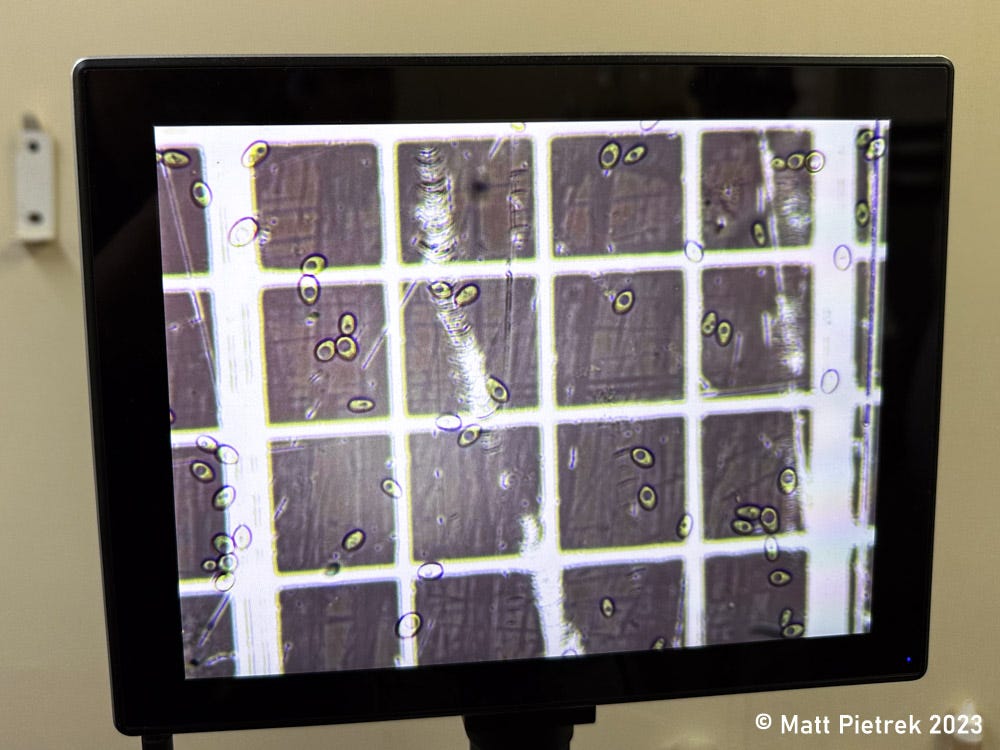

The eastern end of the structure is where the column wash’s yeast propagation and pre-fermentation occur. There is also a good view of the sugar factory and distillery’s molasses tanks. The tanks were once topped up directly from the sugar factory, but molasses now travels by tanker truck to the facility.

On the opposite end of the fermentation structure, a steady flow of fermented wash travels across the surface of an open rectangular tank. Below the wash’s surface, rubber “fingers” capture solids from the wash as it travels past. Removing solids from the wash keeps the column still’s plates operating at peak efficiency for a longer duration.

A quick but careful stroll across the elevated walkway brings you face-to-face with the four-column still. The rectifying column has 76 plates, allowing the production of very pure alcohol if so desired. When all parts of the rum-making process run smoothly, the column can run continuously for a month before stopping for maintenance.

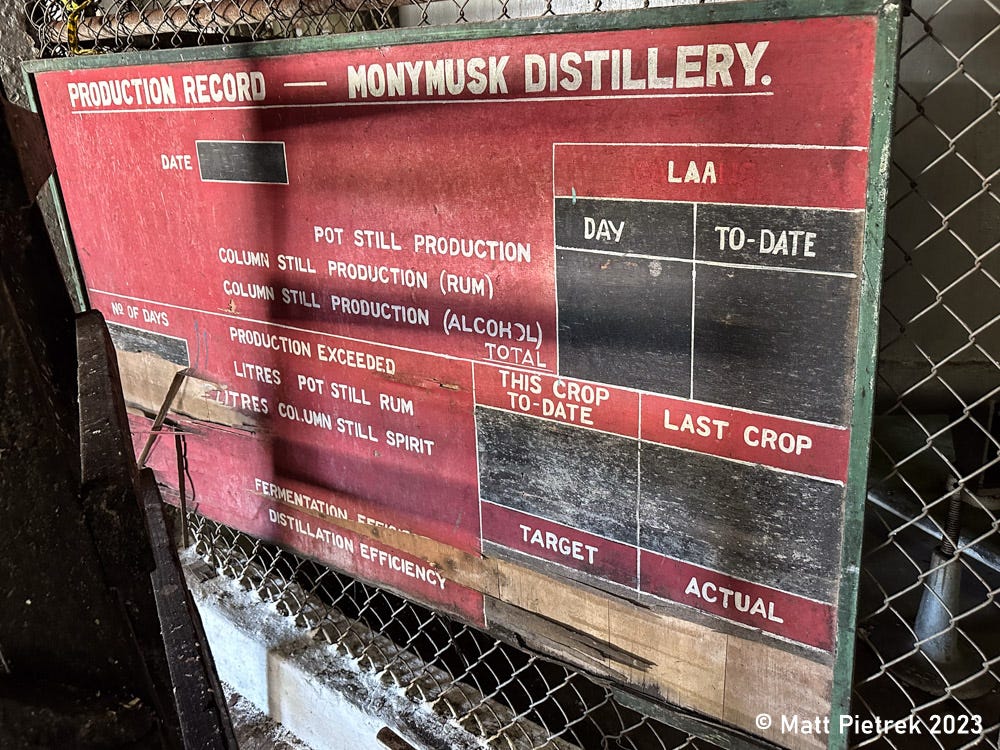

Following a quick lab tour, our attention turned to the pot distillation section. During the short walk to the pot stills, I noticed the long-retired “production status” signboard from when the distillery was known as Monymusk.

While Long Pond makes NRJ’s heaviest rum marques, Clarendon is also very capable of making quintessentially funky rum. Some of the pot still fermentations use cane acid to create marques up to 600 gr/hlAA of esters.

During my 2016 Clarendon visit, I didn’t know what cane acid was or how it was made. I immediately recognized the cane acid tanks this time and captured impressive images, including cane stalks protruding from the liquid’s surface.

Another thing I learned about during this visit was pre-fermentation, which is the intermediate step between yeast propagation and full-on fermentation. Clarendon’s pre-fermentation for pot distillation is temperature-controlled, albeit without fancy computer-controlled refrigeration equipment. Rather, a metal pipe punctured with numerous holes hangs over the pre-fermentation tanks, drizzling water over their tops and sides.

Clarendon’s pot still fermentation area is a glorious sight. Twenty-four open tanks, each holding 95,000 liters, are arranged in rows separated by elevated walkways enabling access to the tank tops. Together, they constitute 2.2 million liters of (theoretical) fermentation capacity.

The fermentation “head” on the tanks in active fermentation is everything you imagine a high-ester, multi-week fermentation to look like. Of course, not all 24 tanks are actively fermenting concurrently. Some are being drained, filled, or serviced.

While two double retort pot stills currently reside at Clarendon, one was tucked away behind a very tall curtain and undergoing repairs during our visit. A few meters from the lone visible still, I noted a slightly elevated concrete pad on the floor. Upon asking about it, I learned that Clarendon once had four double retort stills arranged in a single row. The pad I noticed is where one of those stills rested. The two “missing” stills now reside at Long Pond.

Clarendon’s blending hall contains numerous large tanks holding different types of rum. A few tanks sported labels that may be marques I’ve yet to come across. (Hmm…..) From here, rum destined to be aged travels to NRJ’s aging facility. However, that may change shortly, as there are plans to build aging warehouses in a field adjoining the distillery.

My photographic walkthrough of Jamaican rum distilleries ends for now. I may later share photos from the now-defunct Innswood distillery, which serves as the aging facility for National Rums of Jamaica. Until then, I’ve got a full plate of other rummy posts to share in the new year.